The MSA G1 SCBA Manual is your essential guide to operating, maintaining, and ensuring safety with the G1 SCBA system. It provides comprehensive instructions and critical safety procedures for firefighters and industrial users alike, ensuring optimal performance and compliance with standards.

Overview of the MSA G1 SCBA System

The MSA G1 SCBA is a cutting-edge self-contained breathing apparatus designed for firefighters and industrial users. It integrates advanced technology, including real-time monitoring and connectivity, to enhance safety and performance. The system is part of the MSA Connected Firefighter Platform, enabling seamless communication and data sharing. With its robust design and user-friendly interface, the G1 SCBA ensures reliable air supply and critical situational awareness. The manual provides detailed guidance on its operation, maintenance, and integration capabilities.

Importance of the Manual for Safe and Effective Use

The MSA G1 SCBA Manual is vital for ensuring safe and effective use of the system. It provides detailed instructions for operation, maintenance, and troubleshooting, preventing malfunctions and enhancing user safety. Proper adherence to the manual minimizes risks and ensures compliance with safety standards; Regular updates and clear guidelines help users stay informed and proficient, making the manual an indispensable resource for firefighters and industrial personnel relying on the G1 SCBA in critical environments.

Key Features and Benefits of the MSA G1 SCBA

The MSA G1 SCBA combines advanced technology and ergonomic design, offering enhanced safety, connectivity, and comfort. Its features include real-time monitoring, extended battery life, and customizable configurations to meet diverse operational needs, ensuring optimal performance in high-stress environments.

Advanced Technology and Connectivity

The MSA G1 SCBA features cutting-edge technology, including a high-resolution digital display for real-time monitoring of vital metrics. Its advanced connectivity options enable seamless integration with MSA’s Connected Firefighter Platform, allowing for remote monitoring and data sharing. The system also supports Bluetooth connectivity for enhanced communication and coordination in the field, ensuring firefighters stay informed and connected during critical operations.

Enhanced Safety and Comfort Features

The MSA G1 SCBA is designed with enhanced safety and comfort in mind, featuring an ergonomic backpack for reduced strain and improved mobility. The padded harness ensures a secure fit, while the adjustable waist strap accommodates various body types. The system also includes a voice amplification feature for clear communication and a lumbar support pad for added comfort during extended use. These features minimize stress and maximize operational efficiency in demanding environments.

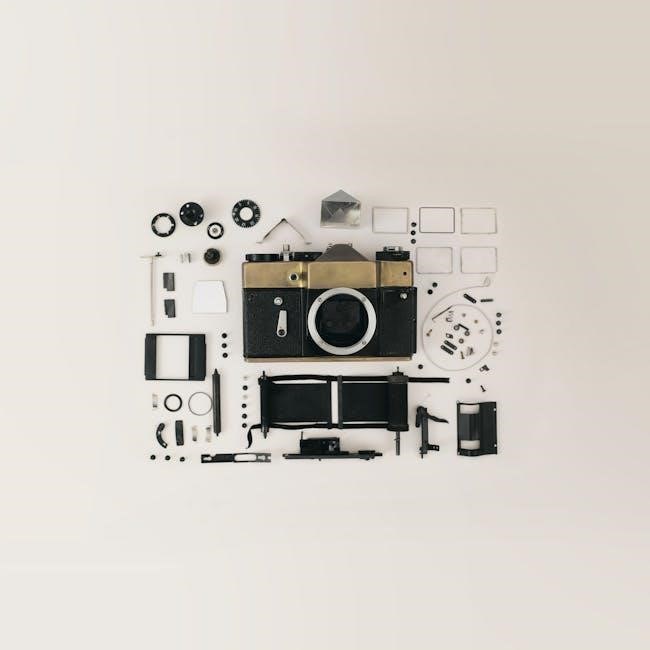

Components and Parts of the MSA G1 SCBA

The MSA G1 SCBA consists of a cylinder, regulator, facepiece, and harness, ensuring reliable air supply and comfortable wear during operations.

Primary Components of the SCBA System

The MSA G1 SCBA includes essential components like the air cylinder, pressure regulator, facepiece, breathing hose, and electronic control module. These parts work together seamlessly to deliver reliable air supply, monitor pressure levels, and ensure clear communication. The system is designed for optimal performance in hazardous environments, with each component engineered to meet stringent safety standards and user needs.

Additional Accessories and Configurations

The MSA G1 SCBA supports various accessories to enhance usability, such as integrated communication devices, buddy hoses, and customizable harnesses. Optional configurations include different cylinder sizes, pressure gauges, and electronic modules for real-time monitoring. These accessories and configurations allow users to tailor the SCBA to specific needs, ensuring versatility in diverse operational settings while maintaining peak performance and safety.

Assembly and Configuration of the MSA G1 SCBA

The MSA G1 SCBA requires precise assembly, starting with attaching the regulator to the cylinder and ensuring all connections are secure. Configuration involves setting up the SCBA to meet specific operational needs, such as adjusting the harness or integrating optional accessories. Proper assembly and configuration ensure optimal performance, safety, and comfort for the user.

Step-by-Step Assembly Instructions

Begin by attaching the cylinder to the SCBA frame, ensuring it is securely locked in place. Next, connect the regulator to the cylinder valve and tighten firmly. Attach the breathing hose to the regulator and route it through the harness. Connect the facepiece to the hose, ensuring a proper seal. Finally, perform a leak check by turning on the cylinder and inhaling through the facepiece. Always follow the manual for precise instructions and safety.

Configuring the SCBA for Specific Applications

Configure the MSA G1 SCBA based on operational needs. For firefighting, enable thermal imaging and communication integration. In industrial settings, adjust the alarm settings for noise-sensitive environments. Use the MSA software to customize alerts and monitor cylinder levels remotely. Attach additional accessories like voice amplifiers or buddy hoses as required. Always consult the manual for application-specific guidelines to ensure optimal performance and safety in diverse scenarios.

Operating Instructions for the MSA G1 SCBA

Follow pre-operational checks and donning procedures. Monitor cylinder levels and ensure proper airflow. Adhere to emergency procedures outlined in the manual for safe and effective SCBA operation.

Pre-Operational Checks and Procedures

Before use, inspect all SCBA components for damage or wear. Check the facepiece, hoses, and cylinders for integrity. Ensure the low-air alarm is functioning and the power switch is in the correct position. Verify cylinder pressure and regulator operation. Perform a facepiece fit test to ensure a proper seal. Review the SCBA’s data logs for any prior issues. Always follow the manual’s guidelines to ensure safe and reliable operation.

Donning and Doffing the SCBA

Ensure the SCBA is fully pre-checked before donning. Begin by securing the waist belt, then shoulder straps, and attach the facepiece. Connect the breathing hose to the regulator and perform a fit test. To doff, disconnect the hose, remove the facepiece, and release the shoulder and waist straps. Store the SCBA upright in a cool, dry place after use. Always follow proper sequences to maintain safety and equipment integrity.

Safety Guidelines and Precautions

Adhere to all safety guidelines when using the MSA G1 SCBA. Conduct thorough pre-use checks, ensure proper training, and follow operational procedures to minimize risks and ensure reliable performance.

General Safety Practices for SCBA Use

Always follow established safety protocols when using the MSA G1 SCBA. Ensure proper training and familiarization with the equipment before use. Conduct regular inspections of the SCBA and its components to maintain functionality. Use the device in well-ventilated areas whenever possible, and never operate it in oxygen-deficient environments without proper precautions. Adhere to the manufacturer’s guidelines for donning and doffing to ensure a secure fit and optimal performance. Avoid exposure to extreme temperatures or hazardous chemicals that could compromise the equipment’s integrity.

Emergency Procedures and Malfunction Responses

In emergencies, remain calm and follow established protocols. If the SCBA malfunctions, activate the emergency bypass to ensure continuous air supply. Exit the hazardous environment immediately and proceed to a safe location. Conduct a buddy check to ensure all team members are accounted for and safe. Report the incident to your supervisor and avoid reuse of the SCBA until it has been inspected and approved. Always prioritize personal safety and follow manufacturer guidelines for emergency responses.

Maintenance and Inspection of the MSA G1 SCBA

Regular maintenance and inspection are critical to ensure the SCBA operates reliably. Check air cylinders, hoses, and facepiece for damage. Replace worn or faulty components immediately. Follow MSA guidelines for inspection schedules and cleaning procedures. Proper upkeep ensures safety, performance, and compliance with certification standards. Always refer to the manual for detailed instructions.

Regular Maintenance Requirements

Regular maintenance is essential for optimal performance of the MSA G1 SCBA. Users must inspect air cylinders, hoses, and facepiece components for damage or wear. Replace seals, O-rings, and other perishable parts as recommended by MSA. Clean and sanitize the system after each use to prevent contamination. Adhere to the manufacturer’s maintenance schedule to ensure compliance with safety standards. Proper upkeep extends the lifespan of the SCBA and maintains its reliability in critical situations.

Inspection Procedures and Schedules

The MSA G1 SCBA requires rigorous inspection procedures to ensure reliability. Conduct daily visual checks of the facepiece, hoses, and cylinders for damage or wear. Perform monthly function tests on regulators and valves. Follow MSA’s inspection schedule, including annual hydrostatic testing of cylinders. Document all inspections and maintain records for compliance. Delays in inspection can compromise safety, so adherence to the schedule is critical. MSA provides detailed guidelines to simplify the process and ensure NFPA standards are met.

Troubleshooting Common Issues

The MSA G1 SCBA may face issues like low air pressure or communication malfunctions. Use diagnostic tools and the manual to identify and resolve problems promptly.

Identifying and Resolving Common Malfunctions

Common malfunctions with the MSA G1 SCBA include low battery, alarm failures, or facepiece leaks. Use the diagnostic tools to identify issues. Refer to the manual for troubleshooting steps. Simple solutions like recharging batteries or tightening connections often resolve problems. For complex issues, contact MSA support. Always follow safety protocols when addressing malfunctions to ensure operator safety and system reliability. Regular maintenance can help prevent many common issues.

Care and Repair of Damaged Components

Proper care and repair of damaged MSA G1 SCBA components are crucial for maintaining performance and safety. Inspect components regularly for wear or damage. Clean parts with approved materials to prevent contamination. For repairs, use only authorized MSA replacement parts. Follow the manual’s guidelines for disassembling and reassembling components. If damage is severe, return the unit to MSA for certified repair. Improper repairs can compromise safety and system integrity, so adherence to protocols is essential.

Integration with the MSA Connected Firefighter Platform

The MSA G1 SCBA seamlessly integrates with the Connected Firefighter Platform, enabling real-time monitoring, enhanced situational awareness, and improved communication for coordinated emergency responses.

Overview of the Connected Firefighter Platform

The MSA Connected Firefighter Platform is a cutting-edge system designed to enhance firefighter safety and operational efficiency. It integrates advanced technologies like real-time monitoring, data analytics, and communication tools. The platform provides incident commanders with a unified view of team members’ statuses, including air supply levels, health metrics, and environmental conditions. It also supports seamless communication and data sharing between crew members and command centers, improving situational awareness and decision-making. This system is tailored to meet the dynamic needs of firefighting operations, ensuring better coordination and safety in high-stress environments.

Configuring and Pairing the G1 SCBA

Configuring and pairing the MSA G1 SCBA with the Connected Firefighter Platform involves initializing the device using MSA’s proprietary software. Users can set up device settings, preferences, and profiles through the platform’s interface. Pairing the SCBA with other compatible devices is achieved via Bluetooth or Wi-Fi connectivity. Ensure firmware updates are installed and synchronization is completed for optimal performance. Follow the manual’s step-by-step guide for accurate configuration and seamless integration with the Connected Firefighter Platform.

Training and Certification for G1 SCBA Use

Comprehensive training programs ensure operators master the G1 SCBA’s functionality, safety protocols, and emergency procedures, with certification verifying competency in its safe and effective use.

Recommended Training Programs and Courses

The MSA G1 SCBA manual highlights comprehensive training programs, including classroom instruction, hands-on workshops, and scenario-based exercises. These courses cover SCBA operation, maintenance, and emergency response. Firefighters and responders can enroll in specialized training sessions offered by MSA-certified centers. Online modules and recurrent training ensure continuous skill development. These programs emphasize practical application and real-world scenarios to prepare users for safe and effective SCBA use in high-stress environments.

Certification Requirements for Operators

Operators must complete MSA-approved training programs and meet specific certification criteria. Annual recertification is required to ensure proficiency with the G1 SCBA. Certification involves passing written exams and practical assessments, demonstrating competence in SCBA operation, maintenance, and emergency procedures. Adherence to NFPA standards is mandatory, and operators must stay updated on system enhancements and safety protocols to maintain compliance and ensure safe, effective use of the equipment in critical situations.

Compliance and Standards

The MSA G1 SCBA is designed to meet rigorous industry standards, ensuring reliability and safety. Compliance with NFPA and other regulations is prioritized for optimal performance and user protection.

NFPA and Other Relevant Standards

The MSA G1 SCBA is fully compliant with NFPA 1981: Standard on Open-Circuit Self-Contained Breathing Apparatus for Emergency Services. It meets rigorous testing requirements for safety, performance, and durability. Additionally, it adheres to NIOSH certification standards and international regulations like EN 137:2006. Compliance ensures the SCBA operates reliably in hazardous environments, providing users with trusted protection. Adherence to these standards underscores MSA’s commitment to delivering high-quality, reliable respiratory protection equipment.

Ensuring Compliance in Different Applications

The MSA G1 SCBA is designed to meet compliance requirements across various applications, including fire service, industrial, and emergency response. It supports multiple configurations to suit different operational needs while maintaining adherence to safety standards. Proper setup, as outlined in the manual, ensures compatibility with specific breathing gas standards and communication systems. Regular training and configuration checks are essential to maintain compliance and optimize performance in diverse operational environments.

Accessories and Compatible Products

The MSA G1 SCBA supports a range of optional accessories, including carrying bags, communication devices, and breathing air cylinders, enhancing functionality and user experience.

Optional Accessories for Enhanced Functionality

The MSA G1 SCBA offers various optional accessories to enhance performance and user comfort. These include voice amplifiers, thermal imaging camera attachments, and customizable shoulder straps. Additional breathing air cylinders with varying capacities provide extended operation time, while integrated communication devices ensure clear connectivity in noisy environments. Carrying bags and storage cases protect the SCBA during transport, and interchangeable facepiece options cater to different operational needs, ensuring versatility and adaptability in diverse scenarios.

Compatible Products and Integration Options

The MSA G1 SCBA seamlessly integrates with a range of compatible products, including thermal imaging cameras, voice amplifiers, and communication headsets. It also works with MSA’s Connected Firefighter Platform, enhancing real-time monitoring and data sharing. Additional compatibility with breathing air monitors and incident command systems streamlines operations. These integration options ensure the SCBA functions as part of a cohesive safety ecosystem, improving situational awareness and operational efficiency in high-stakes environments.

The MSA G1 SCBA manual serves as a vital resource for safe and effective use, ensuring users understand its features, operation, and maintenance for optimal performance.

The MSA G1 SCBA manual provides comprehensive guidance on safe and effective use, emphasizing proper operation, maintenance, and emergency procedures. Users must adhere to outlined safety practices to ensure optimal performance and compliance with standards. Regular inspections and training are crucial for maximizing functionality and user safety. By following the manual’s instructions, operators can confidently utilize the SCBA in various applications while minimizing risks. Adhering to these guidelines ensures reliability and longevity of the equipment.

Final Thoughts on the MSA G1 SCBA Manual

The MSA G1 SCBA manual is an essential resource for ensuring safe, effective, and compliant use of the equipment. It provides detailed guidance on operation, maintenance, and troubleshooting, empowering users to maximize performance. By adhering to the manual’s instructions, operators can rely on the SCBA’s advanced technology and durability. This comprehensive guide is a vital tool for firefighters and professionals, reinforcing confidence in the G1 SCBA’s ability to protect lives in critical situations.

Warranty and Support Information

The MSA G1 SCBA is backed by a comprehensive warranty and dedicated support. Users can contact MSA for repairs, replacements, and technical assistance through authorized service centers.

Warranty Details and Coverage

The MSA G1 SCBA is covered by a limited warranty ensuring defective components are repaired or replaced free of charge within the specified period. Coverage typically includes parts and labor for manufacturing defects, with certain exclusions for wear and tear or misuse. Extended warranty options may be available for additional protection. For specific terms, users should review the warranty documentation or contact MSA directly for detailed information.

Contacting MSA Support and Service Centers

For assistance with the MSA G1 SCBA, users can contact MSA support through multiple channels. Visit the official MSA website for regional office contact details, including phone numbers and email addresses. Support centers are available to address technical inquiries, repair requests, and warranty-related matters. Ensure to have the device’s serial number ready for faster service. MSA also provides online resources and FAQs for quick troubleshooting and support.